Product Description:

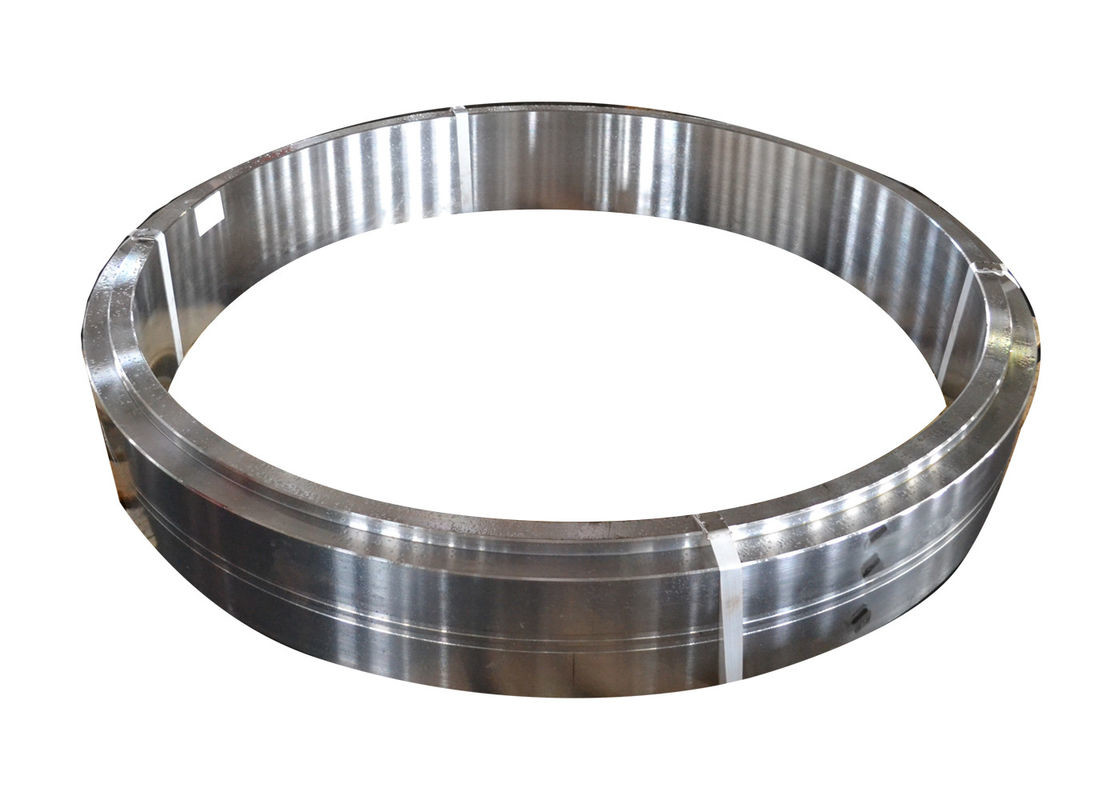

Forged steel rings are essential components widely used in various industrial applications due to their exceptional mechanical properties and reliability. Among these, the 42CrMo4 forged rings stand out as a premium choice for engineers and manufacturers seeking durability and strength. Crafted from high-quality forged steel, these rings are designed to withstand extreme conditions while maintaining optimal performance. The forging process enhances the internal grain structure of the steel, resulting in superior toughness and fatigue resistance compared to other manufacturing methods.

The material used in these forged steel rings is 42CrMo4, a chromium-molybdenum alloy steel known for its excellent balance of strength and ductility. This steel grade is highly favored in the production of steel forged products because it offers outstanding mechanical properties, making it suitable for critical applications such as automotive components, heavy machinery, and high-pressure equipment. The 42CrMo4 forged rings provide a reliable solution where high yield strength and dimensional stability are paramount.

One of the key attributes of these forged steel rings is their impressive yield strength of 650 MPa. This high yield strength ensures that the rings can endure significant stress and load without permanent deformation, which is crucial for maintaining the structural integrity of the equipment in which they are installed. The robustness of these rings helps prevent failures in demanding environments, thereby enhancing safety and reducing maintenance costs.

The surface roughness of the forged steel rings is maintained at 3.2 micrometers, which indicates a fine surface finish achieved through precise machining and quality control processes. A controlled surface roughness is vital for ensuring proper fit and function, especially in applications involving rotating parts or sealing surfaces. The smooth yet durable finish of these rings contributes to reduced friction and wear, further extending their service life.

Heat treatment plays a significant role in defining the mechanical properties of the 42CrMo4 forged rings. These rings undergo a quenching and tempering (Q+T) process, which significantly enhances their hardness, strength, and toughness. Quenching rapidly cools the steel from a high temperature, forming a hard martensitic structure, while tempering relieves internal stresses and improves ductility. This combination ensures that the forged steel rings can perform reliably under dynamic and high-stress conditions.

It is important to note that these forged steel rings do not undergo any additional surface treatment beyond the heat treatment process. Despite the absence of surface coatings, the inherent properties of the forged 42CrMo4 steel and the controlled surface roughness provide excellent resistance to wear and fatigue. This makes the rings suitable for applications where surface treatments might not be necessary or could interfere with the ring’s performance.

Steel forged products like the 42CrMo4 forged rings are favored in industries such as automotive, aerospace, construction, and heavy machinery manufacturing. Their ability to maintain structural integrity under harsh operating conditions makes them indispensable for critical components such as gears, bearings, flanges, and couplings. The forging process imparts superior mechanical properties that ensure consistent quality and reliability, distinguishing these rings from cast or machined alternatives.

In summary, forged steel rings made from 42CrMo4 steel represent an ideal solution for applications requiring high strength, durability, and precision. With a yield strength of 650 MPa, a surface roughness of 3.2, and enhanced mechanical properties achieved through quenching and tempering heat treatment, these forged steel rings deliver outstanding performance in demanding environments. Their robust construction and excellent mechanical characteristics make them a top choice among steel forged products, ensuring longevity and safety in various industrial applications.

Features:

-

Product Name: Forged Steel Rings

-

Size Range: 1000-7800mm

-

Application: Gearbox Rings

-

Thickness: 250mm

-

Yield Strength: 650 MPa

-

High-quality forged steel rings designed for durability and performance

-

Manufactured as part of premium steel forged products

-

Ideal for use in various industrial applications requiring reliable steel forged products

Technical Parameters:

|

Application

|

Gearbox Rings

|

|

Surface Treatment

|

N/A

|

|

Yield Strength

|

650 MPa

|

|

Thickness

|

250 mm

|

|

Shape

|

RINGS

|

|

Surface Roughness

|

3.2

|

|

Hardness

|

240-320

|

|

Size

|

1000-7800 mm

|

|

Elongation

|

N/A

|

|

Heat Treatment

|

Q+T

|

Applications:

The FY brand, with its model number FY001, proudly presents high-quality Forged Steel Rings manufactured in China, designed to meet the rigorous demands of various industrial applications. These alloy forged rings, crafted with exceptional precision, offer dimensional accuracy ranging from 1000mm to 7800mm, and a consistent thickness of 250mm, making them an ideal choice for heavy-duty engineering projects.

One of the primary application occasions for FY’s Alloy Steel Forged Rings is in the manufacturing of gear rings used in automotive, aerospace, and heavy machinery sectors. The superior yield strength of 650 MPa ensures that these forged steel rings can withstand high mechanical stresses and loads, providing durability and reliability in critical gear assemblies. Their excellent surface roughness of 3.2 further enhances the performance by reducing friction and wear, thus extending the lifespan of the gear rings.

In addition to gear rings, FY’s forged rings are widely utilized in the production of large-diameter bearings, flanges, and structural components in industries such as construction, mining, and power generation. The combination of robust material properties and precise dimensional control allows these alloy forged rings to maintain integrity under extreme operating conditions, including high pressure and temperature environments.

These Alloy Steel Forged Rings are also favored in the oil and gas sector, where the demanding environments necessitate components that can resist corrosion and mechanical fatigue. Thanks to the advanced forging techniques employed by FY, the rings demonstrate excellent toughness and resistance, ensuring safety and reliability in pipeline flanges and pressure vessel applications.

Furthermore, the versatility of FY001 forged steel rings makes them suitable for custom engineering solutions where specific dimensional accuracy and mechanical properties are critical. Whether used in heavy equipment manufacturing or specialized industrial machinery, these forged steel rings provide a dependable foundation for high-performance applications.

Overall, FY’s forged steel rings combine superior material quality, precise dimensional accuracy, and robust mechanical properties, making them an essential component across various sectors requiring reliable alloy forged rings and gear rings. Their origin from China and adherence to strict quality standards ensure that customers receive consistent and high-performance products tailored for demanding industrial scenarios.

Support and Services:

Our Forged Steel Rings are backed by comprehensive technical support and services to ensure optimal performance and longevity. We provide detailed product documentation, including specifications, material certifications, and usage guidelines to assist you in selecting the right ring for your application.

Our experienced technical team is available to offer expert advice on installation, maintenance, and troubleshooting to help you maximize the efficiency and safety of your forged steel rings. We also offer custom forging solutions and can work with you to develop rings tailored to your specific requirements.

In addition, we provide quality assurance services including rigorous testing and inspection reports to guarantee that each forged steel ring meets the highest industry standards. Should you require any further assistance or have questions regarding our products, our support services are designed to provide timely and effective solutions.

Packing and Shipping:

Each Forged Steel Ring is carefully packaged to ensure maximum protection during transit. The rings are individually wrapped in protective material and placed in sturdy, cushioned boxes to prevent any damage.

For bulk orders, the rings are securely packed in reinforced cartons with appropriate padding to avoid movement and impact. All packages are clearly labeled with handling instructions to ensure safe delivery.

We offer reliable shipping options with tracking available for all orders. Our shipping partners are selected to provide timely and secure delivery to your specified address, whether domestic or international.

Upon receiving your Forged Steel Rings, please inspect the packaging and contents for any signs of damage. Contact our customer service immediately if you encounter any issues.

FAQ:

Q1: What is the brand name of the Forged Steel Rings?

A1: The Forged Steel Rings are manufactured under the brand name FY.

Q2: What is the model number of these Forged Steel Rings?

A2: The model number for these Forged Steel Rings is FY001.

Q3: Where are the Forged Steel Rings made?

A3: These Forged Steel Rings are made in China.

Q4: What materials are used to make the FY Forged Steel Rings?

A4: The FY Forged Steel Rings are made from high-quality forged steel to ensure durability and strength.

Q5: What are the typical applications for the FY001 Forged Steel Rings?

A5: The FY001 Forged Steel Rings are commonly used in industrial lifting, rigging, and construction applications where strong and reliable rings are required.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!